Environmental Test Systems

Environmental Test Systems

Compact vibration test systems for transportation testing

Manufactured products can be exposed to both thermal and mechanical stresses. These should not be considered separately, as the effects may be linked. IMV can supply vibration test systems combined with climatic chambers to provide complete vibration,

temperature and humidity environmental testing. These systems can be custom designed to fit your application.

Chamber for Vertical Excitation

Syn-3HA-40-V

*1 Inner pressure regulator:

Reduces internal pressure fluctuation caused by vibration (standard equipment)

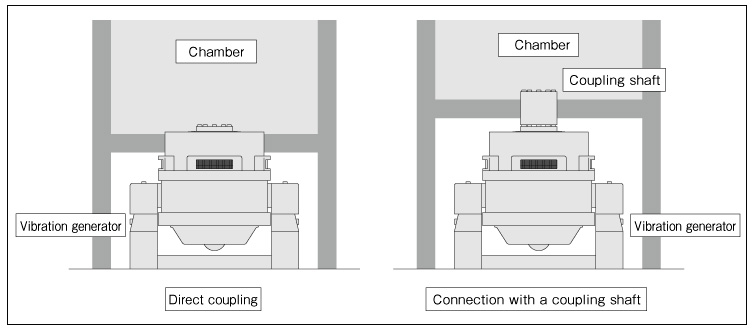

Docking image of combined systems

Specifications

| Internal dimensions | W1000 × D1000 × H1100 mm |

|---|---|

| Temperature range | -40℃ to +150℃ |

| Humidity range | 20% to 95% RH |

| Temperature pull down time | +20℃ → -40℃ In 60 minutes (Curve gradient) |

| Temperature heat up time | -40℃ → +150℃ In 90 minutes (Curve gradient) |

Syn-6HW-30-V

Specifications

| Internal dimensions | W1800 × D1900 × H1500 mm |

|---|---|

| Temperature range | -30℃ to +80℃ |

| Humidity range | 60% to 95% RH |

| Temperature pull down time | +45℃ → -30℃ In 35 minutes (Curve gradient) |

| Temperature heat up time | -30℃ → +80℃ In 25 minutes (Curve gradient) |

Chamber for Both Vertical and Horizontal Excitation

Horizontal slip table combined vibration test system. Combining a rail support for horizontal movement and a lift support for vertical movement, the chamber accommodates testing for both vertical and horizontal axes.

Syn-3HA-70-VH

Vertical Use

Horizontal Use

Rail and lift support

Specifications

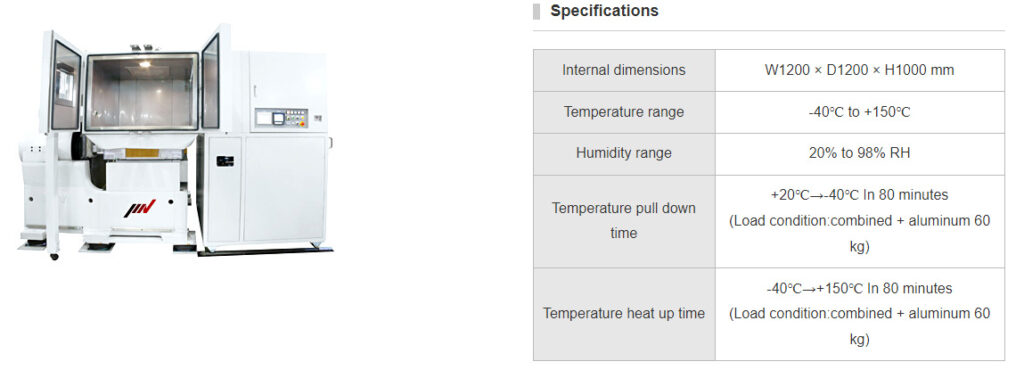

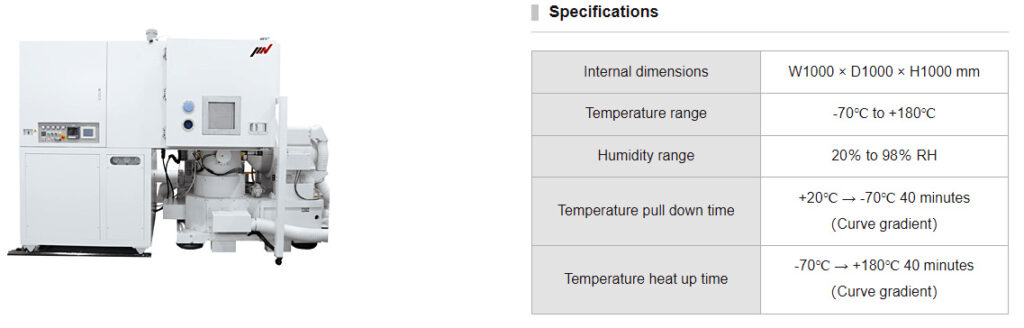

| Internal dimensions | W1000 × D1000 × H1000 mm |

|---|---|

| Temperature range | -70℃ to +180℃ |

| Humidity range | 20% to 98% RH |

| Temperature pull down time | 1℃/ minutes or more(Curve gradient) |

| Temperature heat up time | 2℃/ minutes or more(Curve gradient) |

Video

Shows how easy it is to set up the shaker for different orientations.

Option(Chamber for both Vertical and Horizontal Excitation)

Optional crane

Adding a dedicated crane provides safe and simple loading and unloading of test specimens.

Optional crane and observation door

The vertical base can be attached and detached using the optional crane with the head expander straying mounted on the vibration generator. In addition, operator-friendly environment means such as observation door and body suspension automatic adjustment mechanism etc are equipped.

Side window

With a side window, chamber combination docking is possible with the specimen attached to the vibration generator for vertical excitation use.

Cable bear

Cables and water pipes put together with the cable bear provide safe work environment.

Chamber for Multi-Axis Excitation

- Temperature and humidity chamber for multi-axis vibration test systems.

- Total test time can be reduced by eliminating the need to reconfigure for testing in each axis.

2-axis Syn-4HA-40-M

3-axis Syn-3HA-40-M

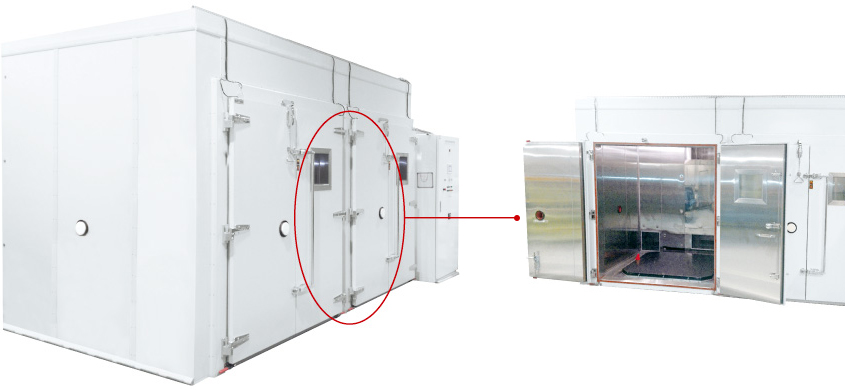

Prefabricated Chamber for Large Specimens

- Large specimens can be tested with a chamber combined test in both vertical and horizontal axes.

Syn-6HA-40-VH

Specifications:

| Internal dimensions | W4000 × D2000 × H2500 mm |

|---|---|

| Temperature range | -40℃ to +120℃ |

| Humidity range | 30% to 95% RH |

| Temperature pull down time | +20℃→-40℃ In 120 minutes (Curve gradient) |

| Temperature heat up time | -40℃→+150℃ In 150 minutes (Curve gradient) |

Docking image of combined systems

Controllers

Chamber Controller

8.4-inch touch panel

Clear display of information and buttons on the 8.4-inch touch-panel. Clear, unambiguous display of all the information required.

Program selection

Up to 100 programs can be stored in memory. Selecting the program to be used is straightforward.

Program editable in PC

Tests can be set up using a spreadsheet.

Programs use the standard CSV file format.

Program confirmation

Test progress is displayed in tabular and graphical formats.

System monitor (option)

Connect to the system monitor by Ethernet. Test status for both shaker and chamber can be monitored remotely.

Integrated control system (option)

Multiple vibration test systems can be control by one system.

Option

Many options are available to make operation easier, such as different door positions and observation window locations.

Observation door

An observation door enables monitoring of the test specimen throughout the test.

Infrared irradiation

Car instrumental panel, door, bumper, or body sections can be tested.

Ceiling observation window

A ceiling observation window allows full visibility of the vibration table and test specimen with no blind-spots.

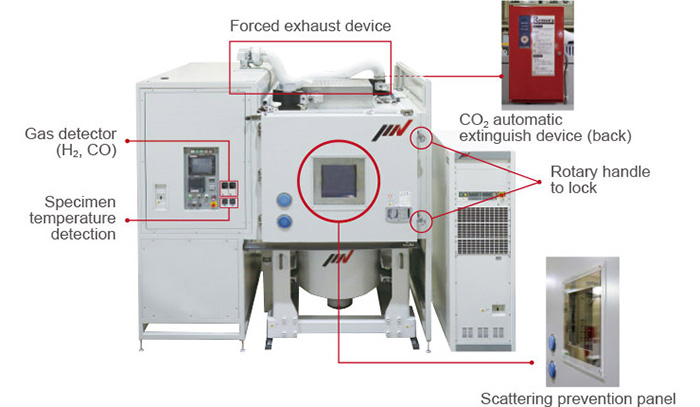

Safety measures for fuel cell tests

Safety measures for fuel cell tests